ole

Punching

ole

Punching

½" Polyethylene Tubing Mounting Instructions

Back To Punches >H ole

Punching

ole

Punching

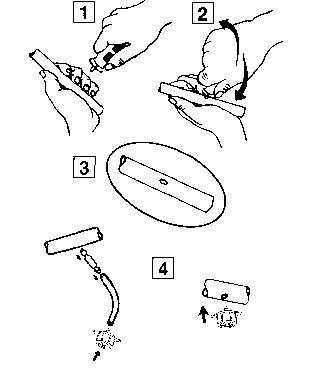

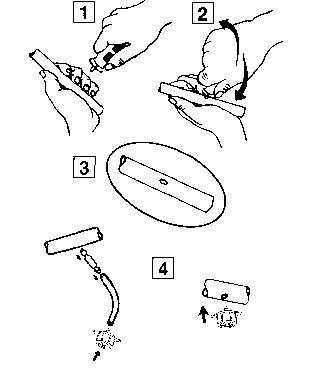

1: Place the Hole Puncher, G280, perpendicular to the ½" hose.

2: To make a hole, cut out a disk from the hose using a twisting motion.

3: It should look like this after you make a hole.

Repeat this process for every hole desired on the tubing.

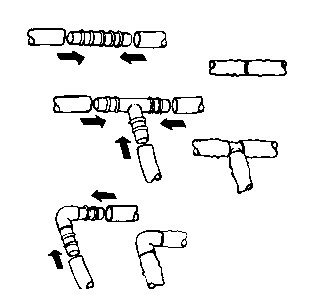

Attach all the connectors and tees to the Tubing

Before attaching the drippers, sprayers

and/or foggers, flush out the system so that any foreign material

that may have entered the line will be removed and will not clog the

drippers or sprayers.

Important things to remember:

1: Only use the hole punch provided to make the holes. If another object is used besides the hole puncher, ragged and uneven holes may be created that will not seal around barbs. This will result in leaks around the connections.

2: Replace the Hole Punch when it becomes dull. The size of the hole will be changed if an attempt is made to re-sharpen the Hole Punch. This will result in leaks around the connections.

Inserting

Fittings

Inserting

Fittings

Cut the hose or hoses to the desired length, making sure that the ends are clean and straight.

Push the ends over for each one all the way.

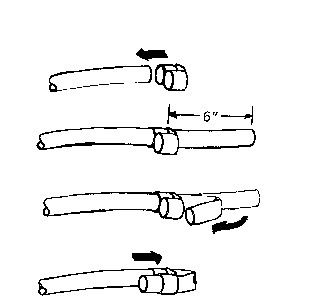

Closing Off Hose Ends

Slide the Hose Clamp over the end of the hose

Slide the clamp along the hose back 6 inches

Fold the hose tightly back and kink it.

Slide the clamp back over the folded end.